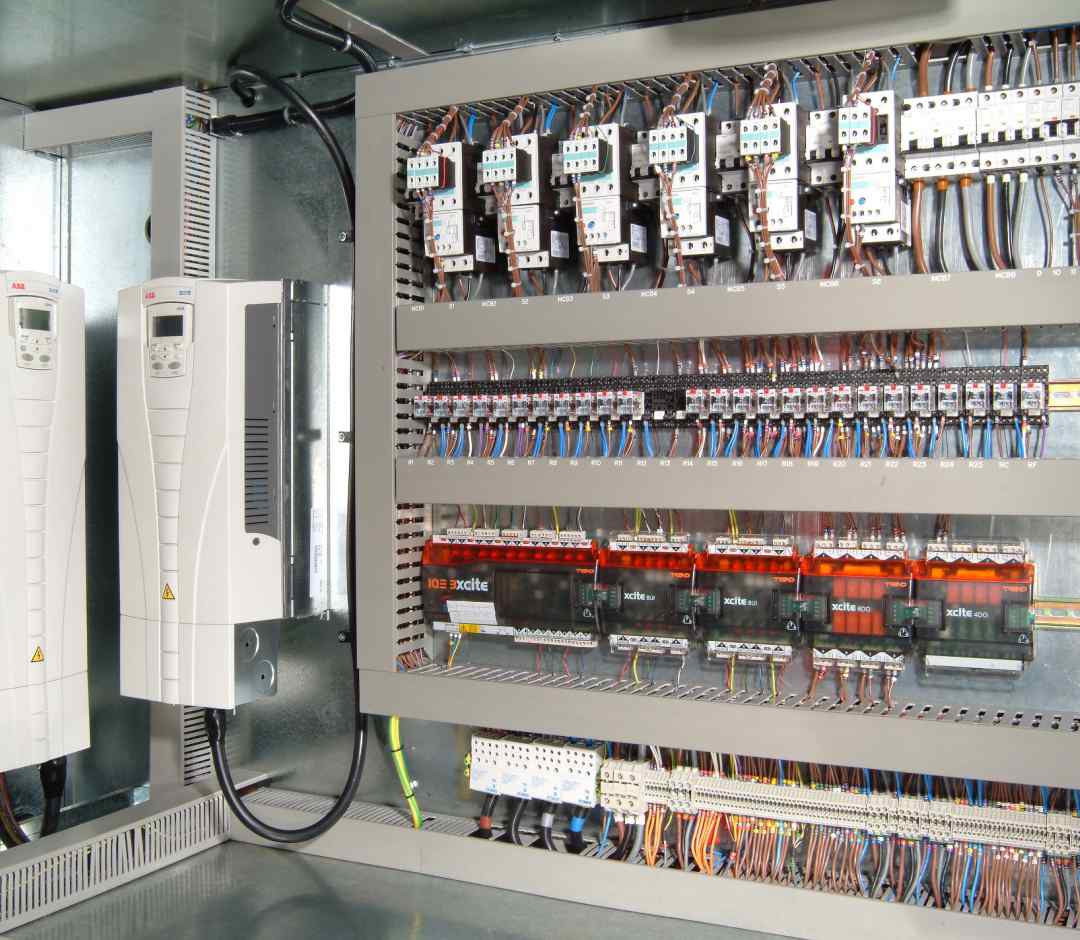

Machines and industrial equipment in manufacturing units need proper control and functions to accomplish different objectives of the processes. All these functions are controlled with the help of an electrical control panel in manufacturing or production.

What is an Electrical Control Panel?

An electrical control panel controls different mechanical functions of various industrial machinery and equipment using electricity. There are two categories of electrical control panels: panel structure and electrical components.

Components of Electrical Control Panel

Here are the different components of the electrical control panel:

- Human Machine Interface (HMI)– It allows a person to operate, control or monitor the machinery with the help of keyboards, switches, buttons, joysticks, and video monitors.

- Network Switches – This is a network hub that helps to connect different network devices with PLC.

- Relays & Contactors – These buttons control small and big functions such as motor, fans, and light.

- Programmable Logic Controller (PLC)– It is the brain of the electrical control panel, which helps control and monitor different machinery processes. It also processes different inputs and gives output for the mechanical functions in the production process.

- Terminal Blocks – It helps in the distribution and organization of wires to an electrical device from different sources.

- Transformers – It reduces the incoming voltage according to the requirement of different components

- Surge Arresters – In case of overvoltage, power surge, or lightning strikes, it protects the electrical components from being damaged.

- Main Circuit Breaker – It handles voltage in the range of 120V – 480V.

Why Is Electrical Control Panel Needed?

Here is why an electrical control panel is needed:

- Fulfill the Objectives of Production

An electrical control panel allows fulfilling the manufacturing and production goals by helping organize and control various mechanical functions of the machinery and industrial equipment.

- Industrial Automation

The process of manufacturing or production can be easily automated with the help of an electrical control panel. It regularly monitors the functions of the equipment.

- Customized Electrical Control Panel

For great control over different machinery and industrial equipment types, industries can also opt for customized electrical control panels. It can help to increase the organizing and control function of the electrical control panel according to the specific industry.

- Equipment Monitoring and Data Collection

It regularly monitors the various machinery and equipment of the industries and generates the data required by the experts to analyze. Thus, it offers reliability over the manufacturing unit.

- Handle Complex Electrical Controls

One can easily handle the complex manufacturing and industrial units with the help of a custom-made electrical control panel.

- Weatherproof and Rust Resistant

The panels can be used in both indoor and outdoor places as they are weatherproof and will not be affected. Also, the rust-resistant property of the panel enables its use in extreme climates.

- Hazard-Proof Electrical Control Panel

The panels are shock-proof from electricity. There is also no risk hazard during fire outbreaks.

- Aesthetic Control Panel

The electrical control panels will not compromise with the beauty standard of the building as these days, one can easily get aesthetically pleasing electrical control panels.

- Process Simplification

The primary need for having an electrical control panel is to simplify the manufacturing or production process. With the help of a panel, one can efficiently operate, organize and design the manufacturing process of various equipment and machinery.

- Decreased Production Cost

Electrical control panels help increase the efficiency of various processes, thereby decreasing the overall cost of production.

- Lower the Risk of Flaws

The risk of undesired outcomes or flaws is reduced due to the enhanced control over the mechanical process of the production.

Thus we can conclude that using electrical control panels for mechanical processes is beneficial and essential.